r i v e r r o a m

large challenges require breaking solutions into components

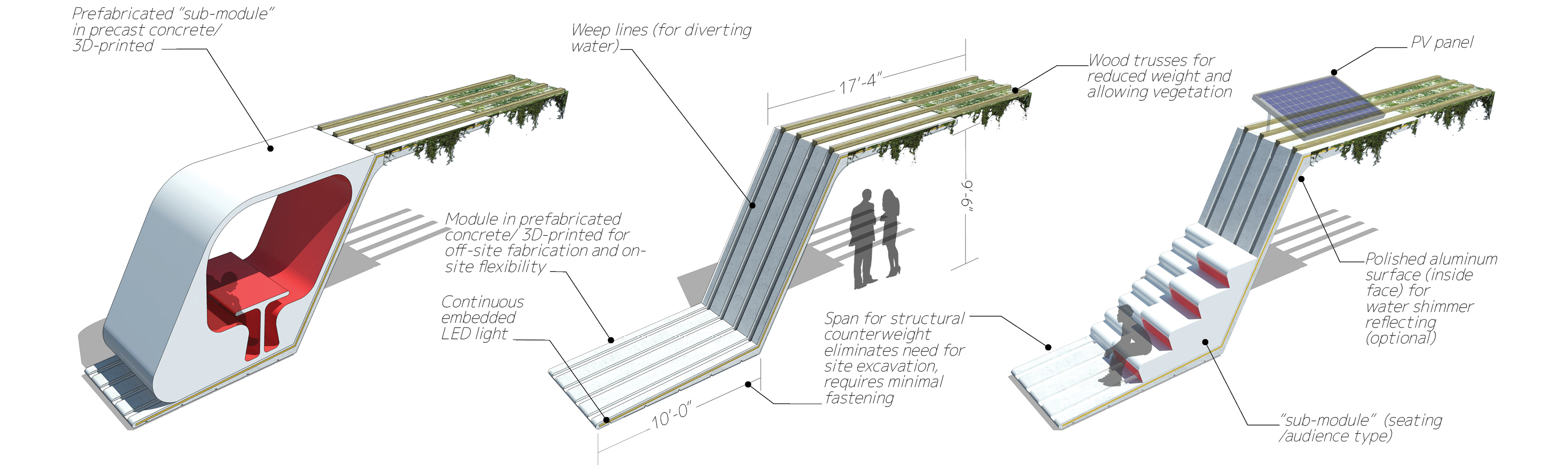

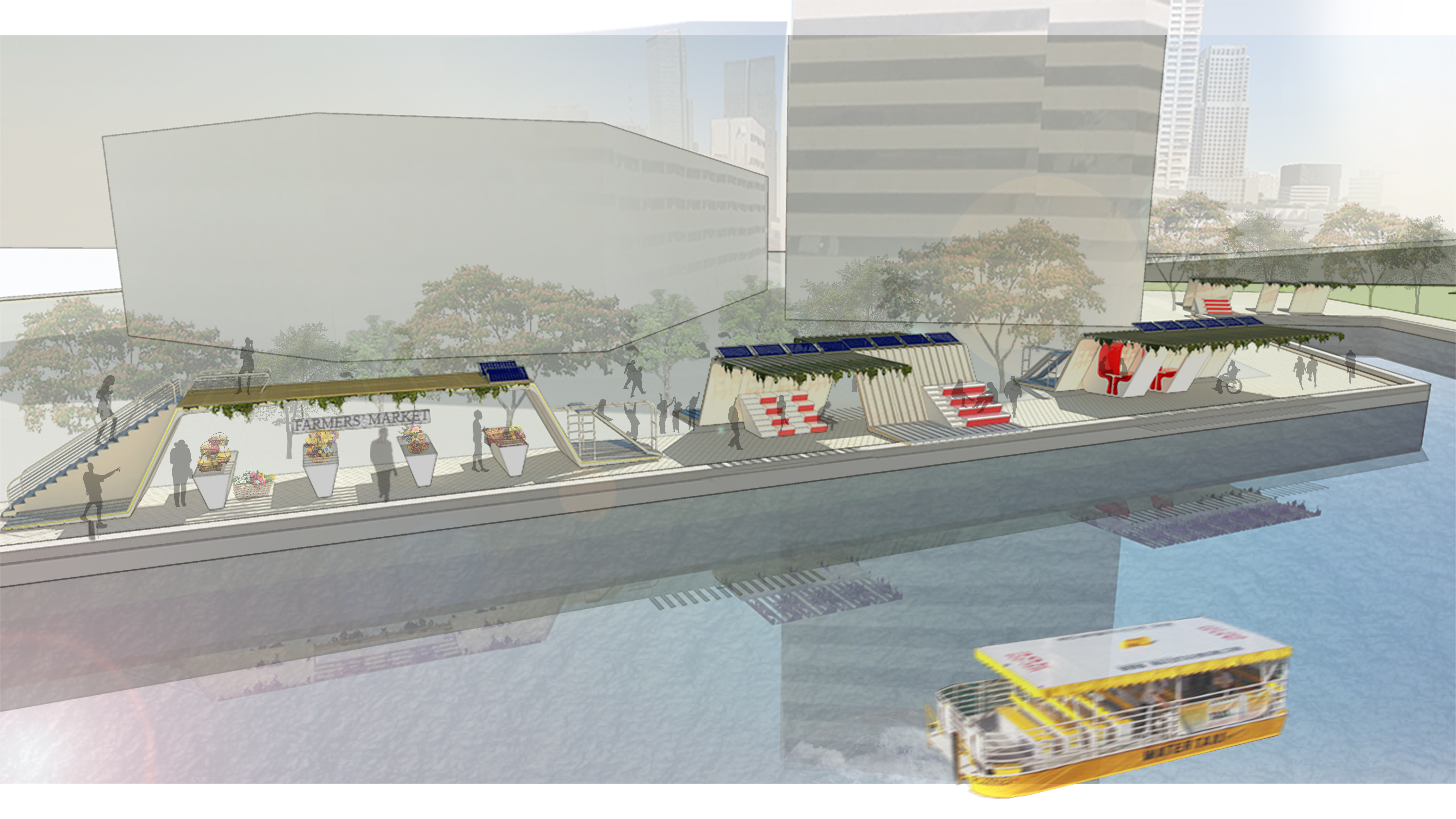

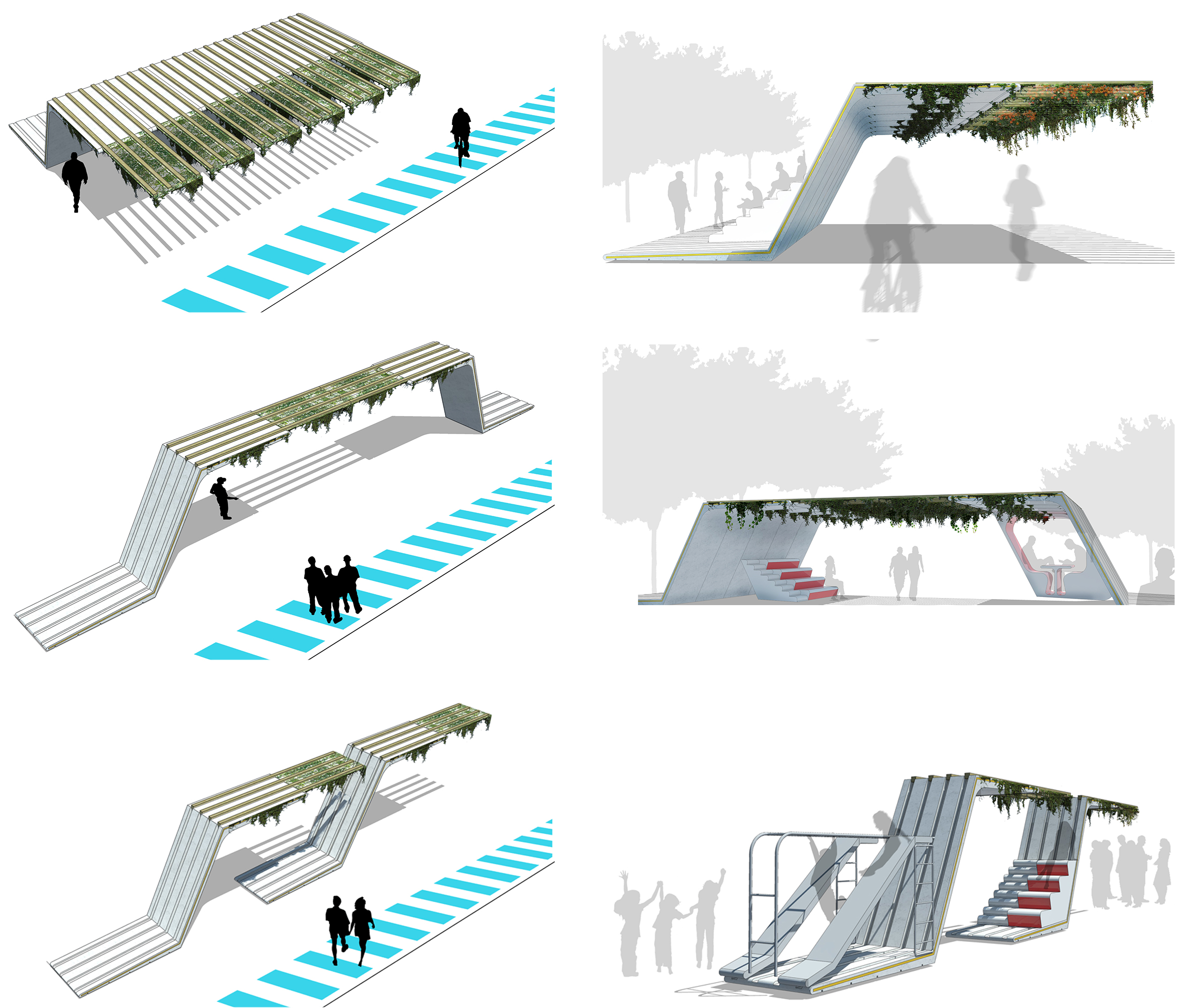

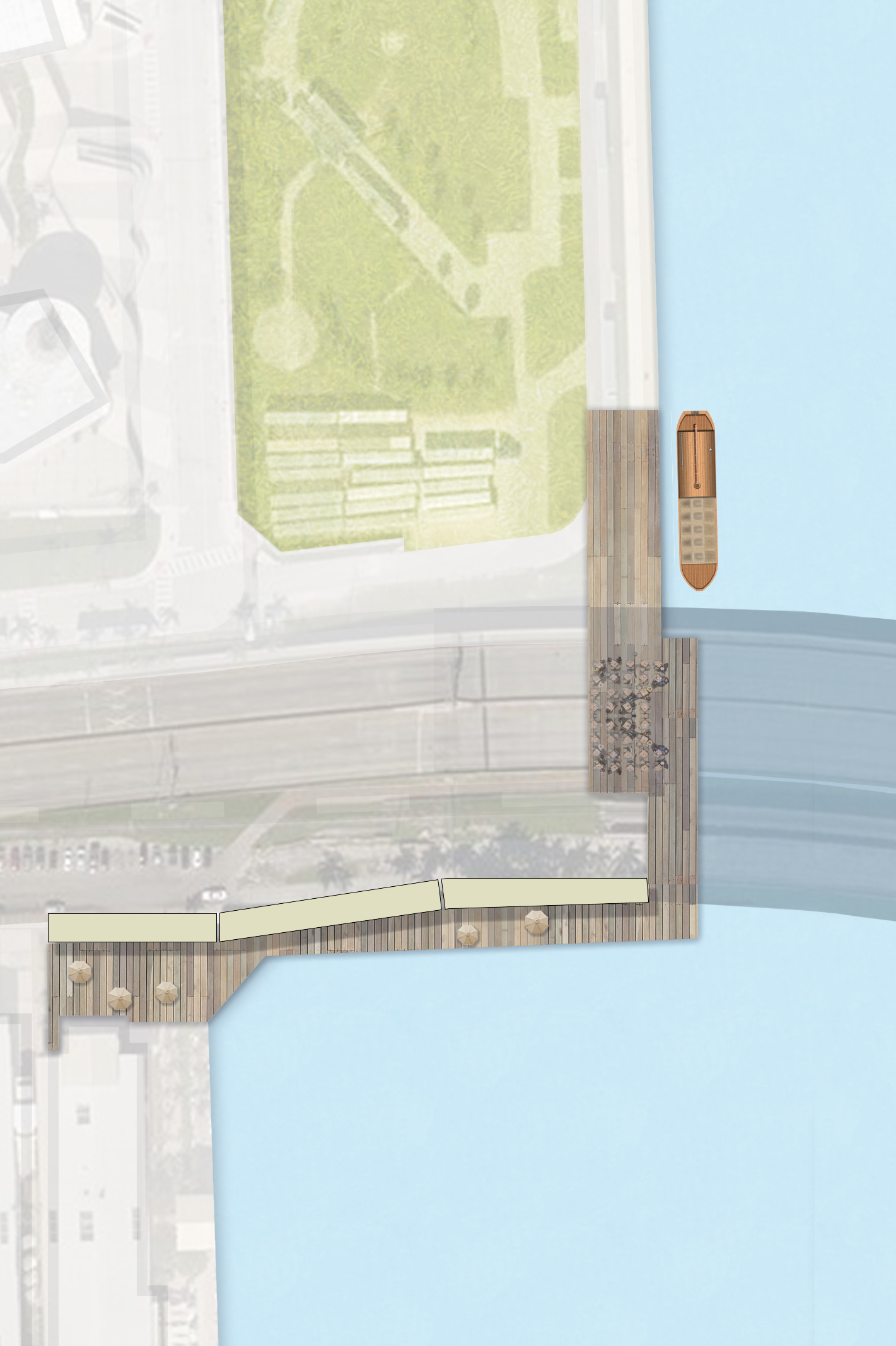

Prefabricated concrete modules and arrangements for the waterfront from SW 2nd ave to the McArthur causeway

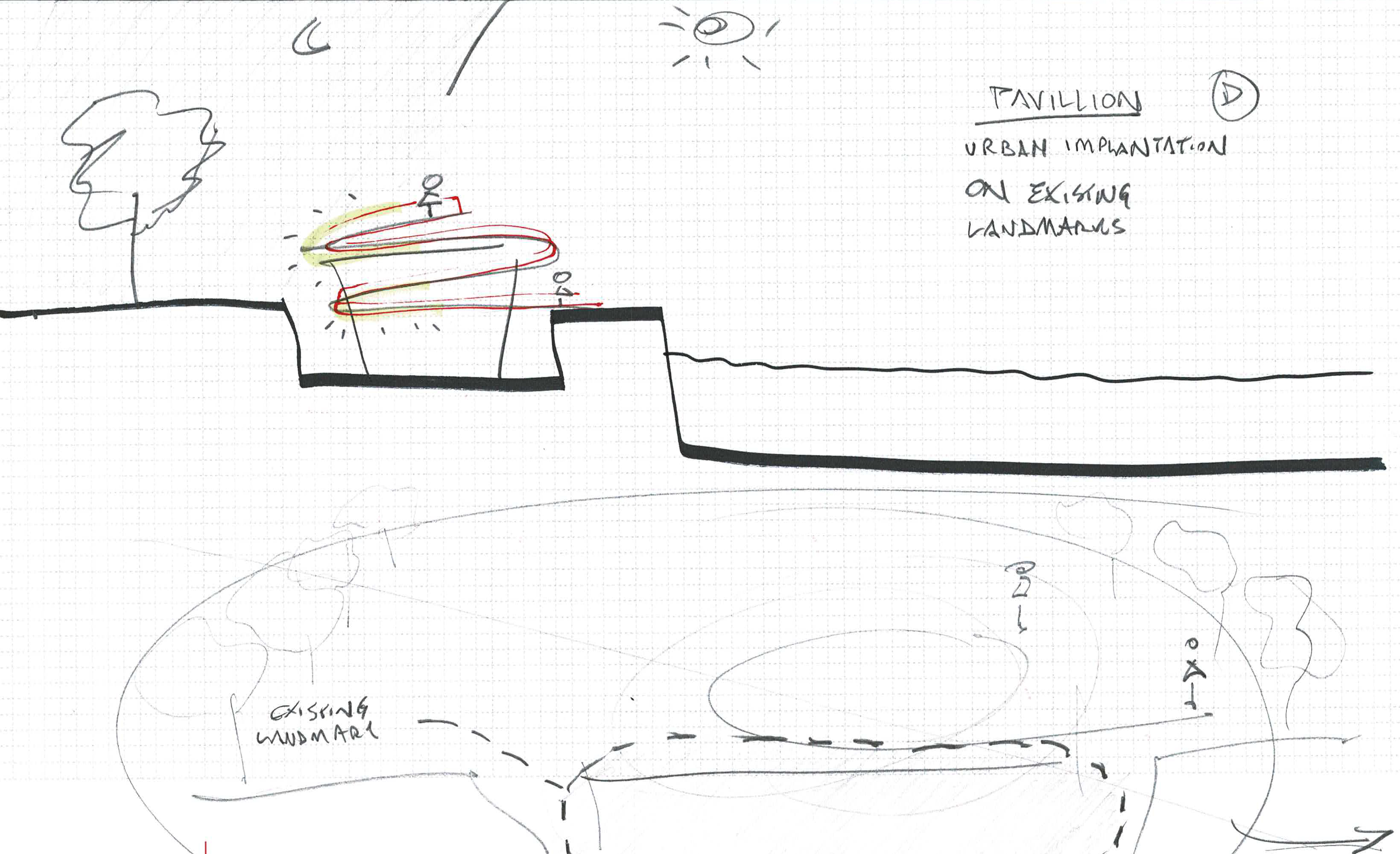

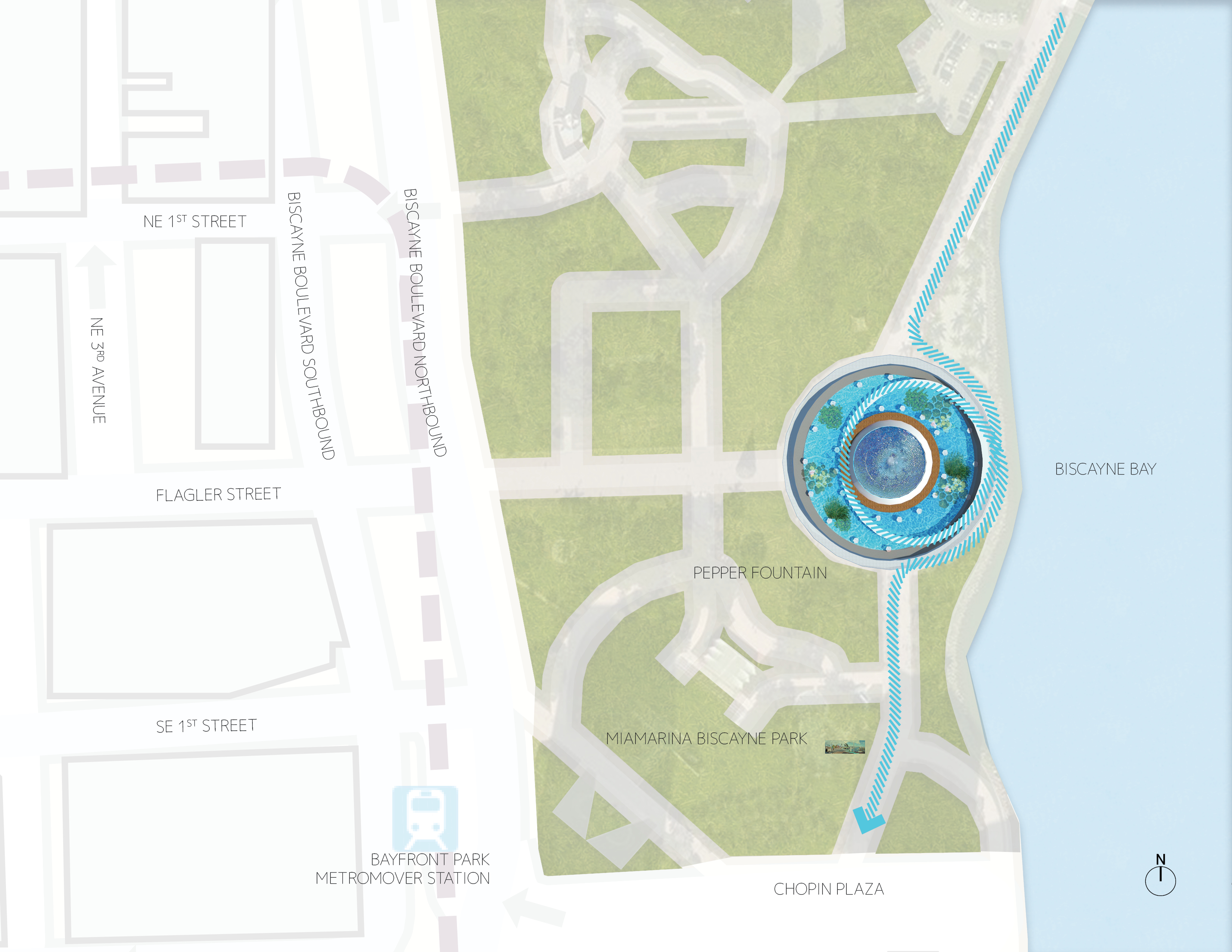

The iconic, yet neglected Pepper fountain is an underused landmark, the vision for the riverwalk engages it by making it an active part of the path.

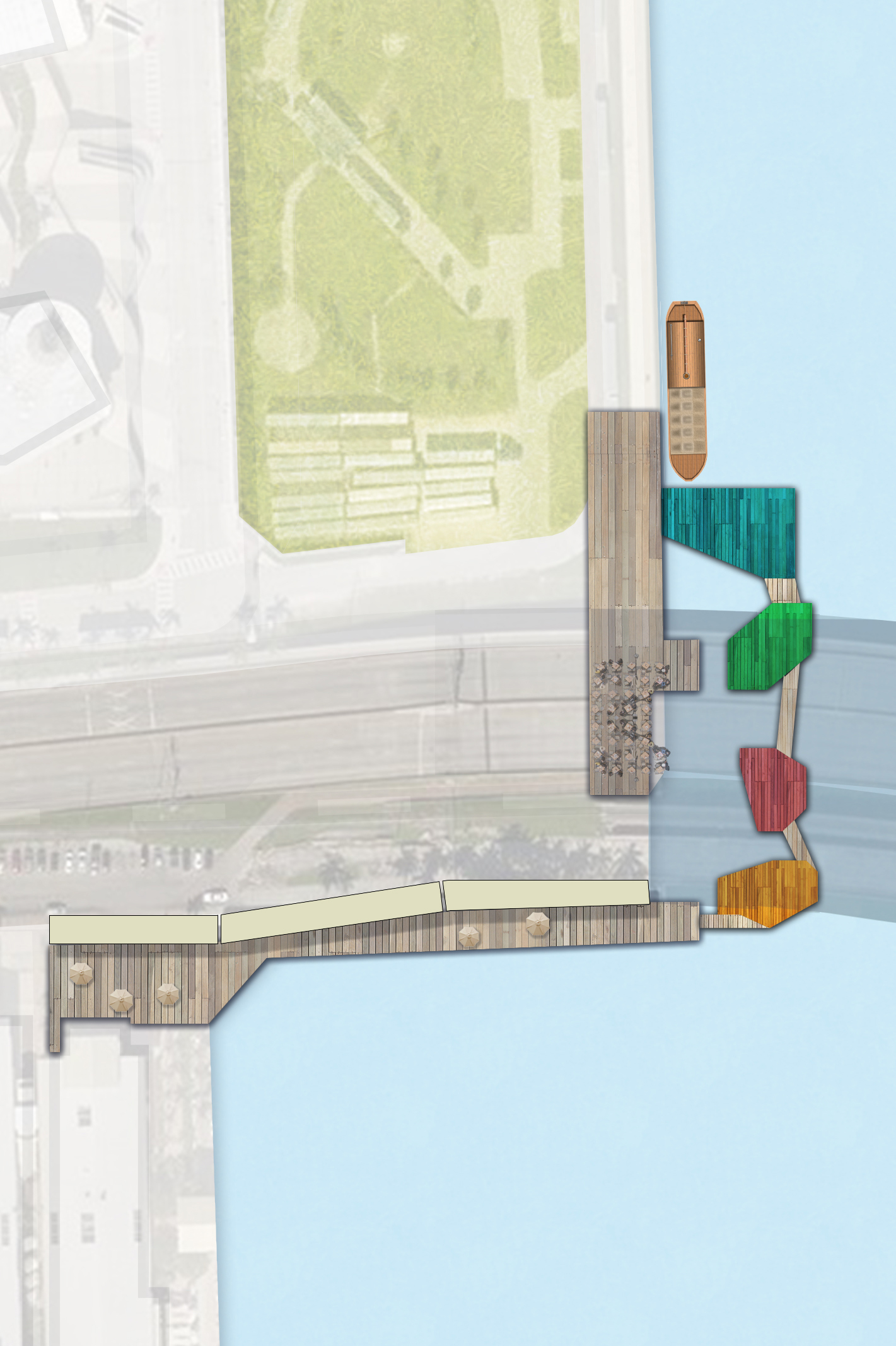

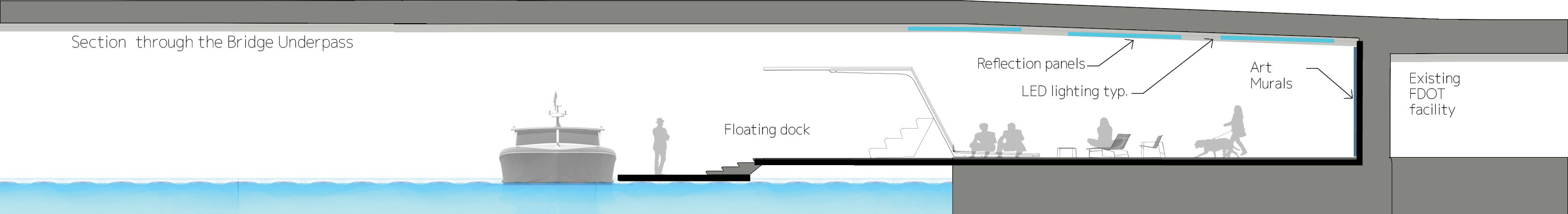

Options for rehabilitation of Port Bridge underpass: Extension of walkway / floating dock walkways

The absence of light contributes to the sense of lack of safety and comfort at the Port Bridge underpass, an important link between destinations of ourRiver Roam proposal. The proposed floating dock provides continuous pedestrian connection and attracts small businesses such as food boats and water taxis. The proposed polished metal sheets fastened to the underside of the existing Port of Miami bridges reflect the sunlight bouncing off the water, dispersing as shimmer that creates a surreal and calm marine atmosphere. At night, LED lights on the bridge underside and on the water surface create an inviting atmosphere.

Miami, FL

year: 2017

role: conceptualization, design, rendering, rendering post-production, modeling, presentation

year: 2017

role: conceptualization, design, rendering, rendering post-production, modeling, presentation

This

strategy

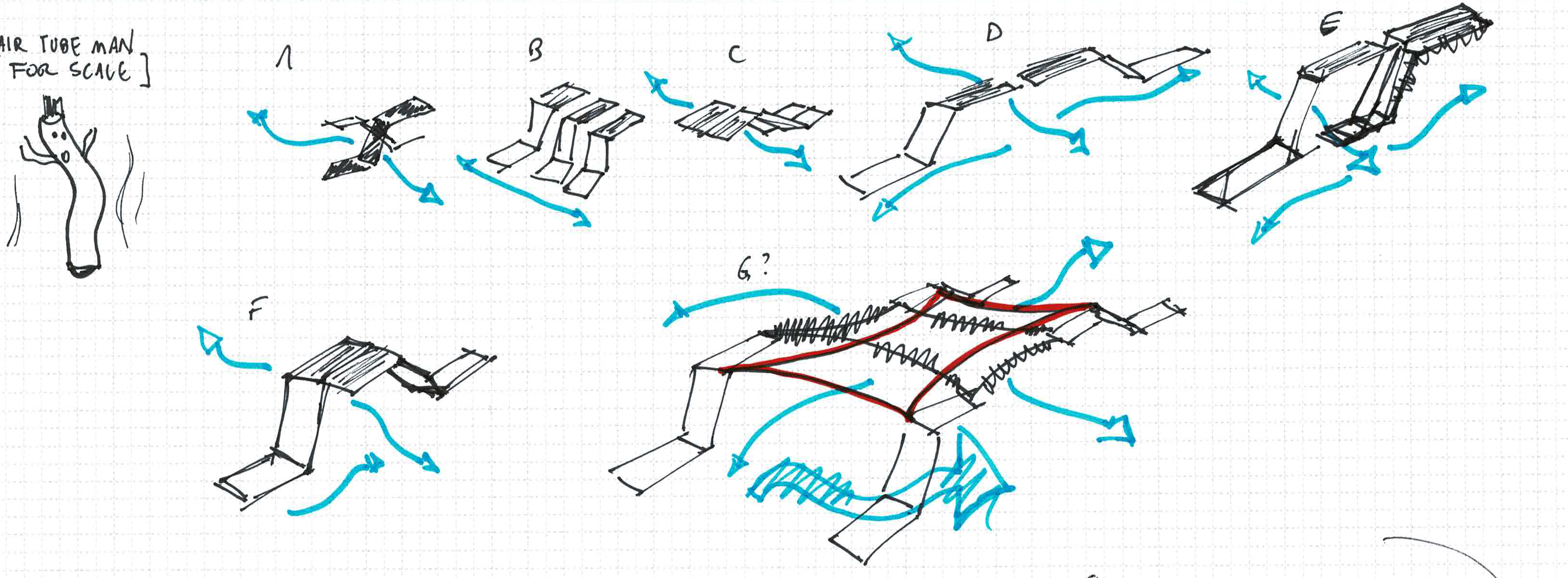

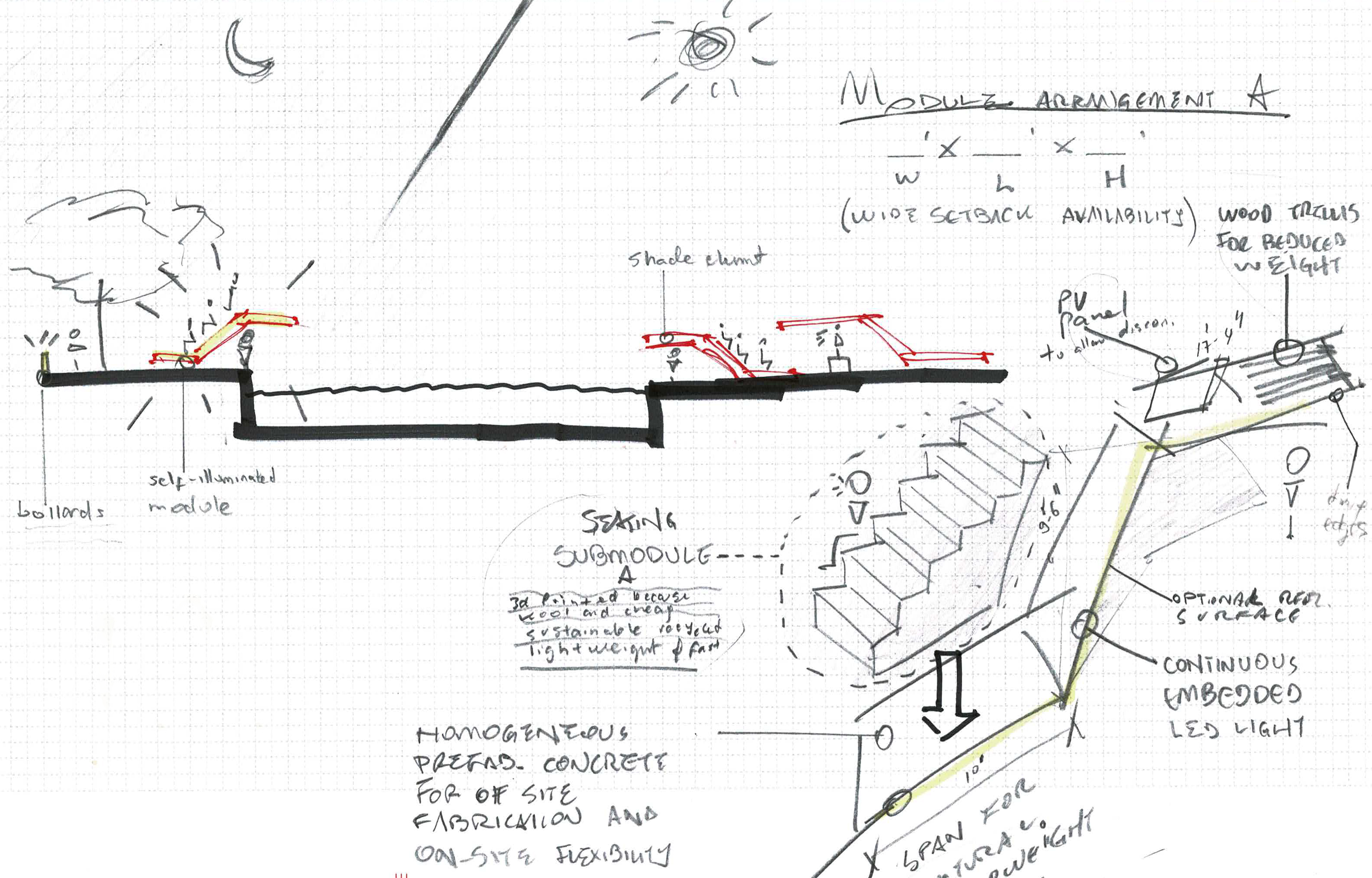

for the Miami River Roam RFP utilizes prefabricated concrete modules which help explore Baywalk and the Miami river. The modules are linear in nature

to accommodate to site conditions where there is little space. They can also be grouped together to form various conditions of shade, illumination, views and activity.

Modularity assists in reducing cost, maximizing flexibility and avoiding site excavation, as the modules are held in place by structural counterweight. Prefabricated “sub-modules” assist in the structural counterweight and in creating activities. These may be dining tables, audience seating, children’s playgrounds, outdoor fitness devices, planters, art murals, etc. In lieu of precast concrete, the modules or the submodules could take advantage of 3D printing technologies, which now have reached building scale, are economical, require less energy to fabricate, reduce construction time, require less labor and utilize recycled materials. The modules can be fastened or removed for storm events.

In collaboration with Iuliia Fomina

Modularity assists in reducing cost, maximizing flexibility and avoiding site excavation, as the modules are held in place by structural counterweight. Prefabricated “sub-modules” assist in the structural counterweight and in creating activities. These may be dining tables, audience seating, children’s playgrounds, outdoor fitness devices, planters, art murals, etc. In lieu of precast concrete, the modules or the submodules could take advantage of 3D printing technologies, which now have reached building scale, are economical, require less energy to fabricate, reduce construction time, require less labor and utilize recycled materials. The modules can be fastened or removed for storm events.

In collaboration with Iuliia Fomina